Repack & Shrink Wrap

CustomerDouble Maxim Brewery

ProfileFollowing the closure of two breweries in 1999, a group of former employees of these two fine companies established the Double Maxim Beer Company Ltd. The success of Double Maxim bottled beer and support of customers made it possible for the business to start brewing again, and in 2007, the purpose-built Maxim Brewery began production at Houghton le Spring.

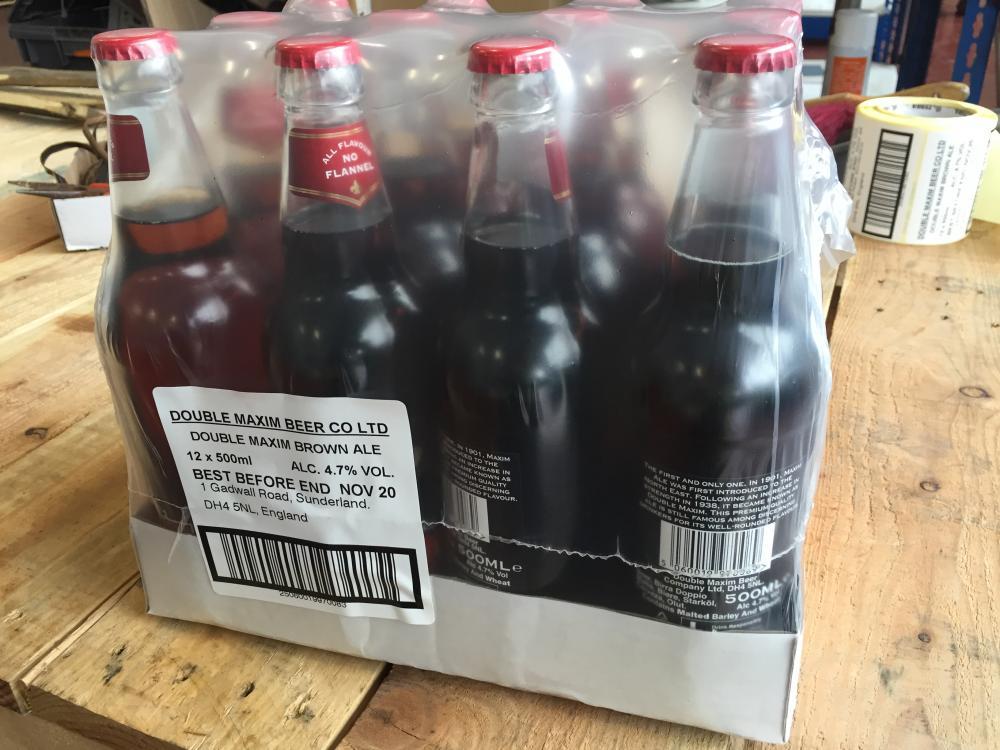

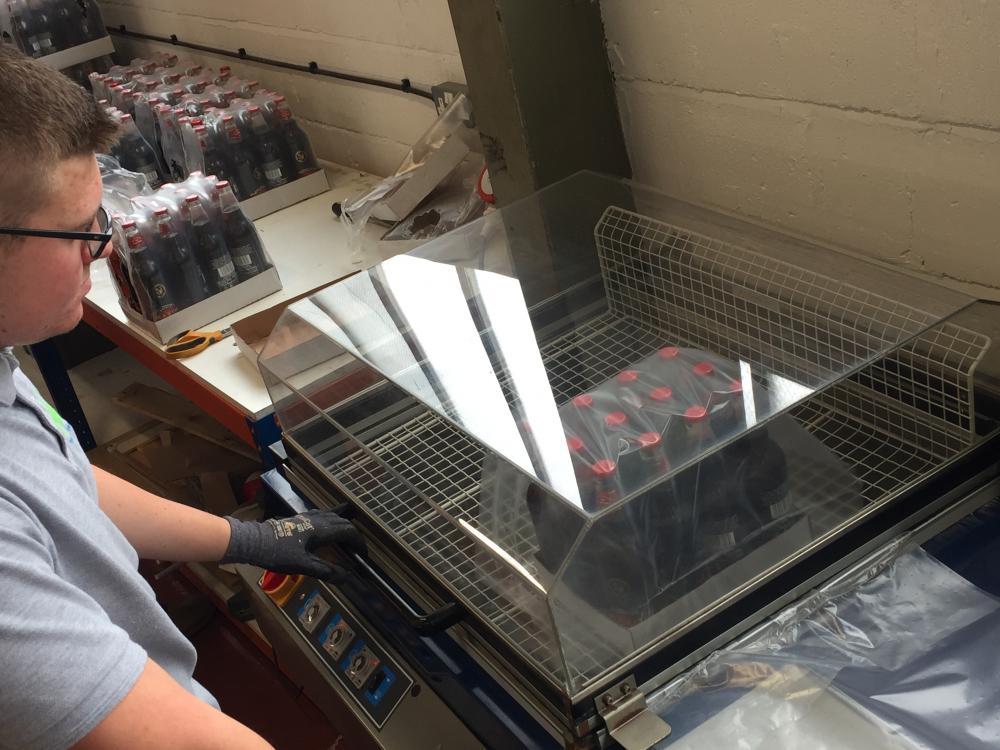

ChallengeThe brewery uses Robinsons Bottling Plant, and on a return journey of bottled Double Maxim Ale back to the brewery, a mishap occurred with the haulier the brewery uses. The cases of ale were not strapped down on the truck properly which meant the pallets were damaged in transit and required attention before they could be forwarded on to suppliers. MCR were contacted after the MD at Maxim Brewery searched for local repackaging and labelling companies. The team were asked to quote based on unpacking damaged pallets, sorting good/bad cases of ale, creating new cases from bottles salvaged, re-shrink wrapping, labelling, and securing onto pallets.

SolutionMCR sorted, repackaged and re-shrink wrapped all damaged cases of ale, as well as labelling and re-stacking the full shipment of pallets. In total the team at MCR handled 1500 cases of ale within a two-day operation. The cases were wrapped securely onto pallets and delivered back to the Double Maxim Brewery at the site in Houghton le Spring, ready for onward distribution to customers.

The team at MCR have been a pleasure to work with on this project. I visited the site to see the extent of the damaged cases, and the team were more than happy for me to see their operation to recover the bottles and re-package them. I was really impressed with the set-up of the unit for this kind of work. I was even given a guided tour of the full site to see if Moody Logistics and Storage may be able to help us as well in the future.

Mark Anderson, Managing Director

Registered in England | Company Number: 07600055